1. This machine adopt Taiwan PLC controller and control each spray gun’s switch independently.

2. Automatic identification infrared sensor is provided to test the product’s length and width. PLC adjusts spray gun’s position automatically.

3. The automatic spray gun is imported from Japan originally or MEIJI spray gun. Each spray gun can be control separately.

4. Waste gas purifying system is provided for the machine, to effectively treat the waste gas generated by the spraying operation before discharge, to maximum prevent environment pollution.

5. The oil supply system includes a set of large‐volume diaphragm pump and a stabilizer in order to provide stable paint flow, ensure stable spraying and easy to

change the paint .

6. The conveyor’s speed is under frequency conversion control, to adapt for varied painting requirements.

7. The paint recovery device can recycle 70%‐80% wasted painting.

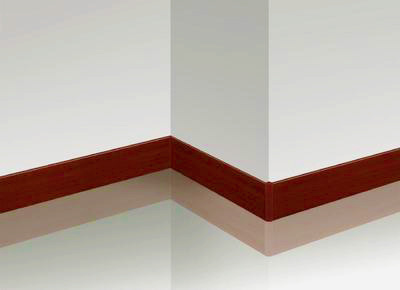

Applicable to all kinds of doors core board, baseboard, marble waist, cabinet doors and other products, aluminum shell and other substrate lines for continuous surface painting.

-

Door core board

-

Base line

-

Marble waistline

-

Cabinet doors