1. Feeding machine adopts several rollers to convey, paint spraying machine adopts automatic spraying method.

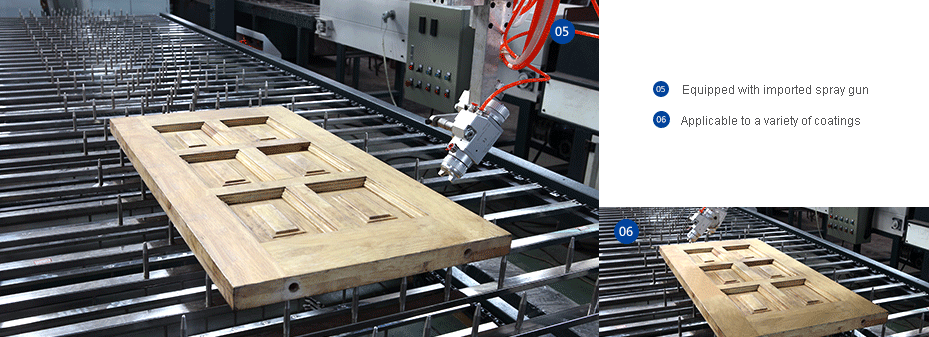

2.Working process: Roller conveyor conveys work‐piece to spraying station, and then scanned the work‐piece’s size, through the calculation of numerical control system to get the spraying trajectory to start painting.

3.Paint spraying machine adopts Taiwan control system, water curtain purification system and ventilation system, which fully embody design concept of environment protection and energy saving.

4.The first paint spraying machine repairs color, then wood line will be conveyed to leveling line with length of 5‐7.5m.

5. The second paint spraying machine sprays topcoat to the wood line, and then the wood line will be conveyed to the second leveling line of length of 15m.

6. Frequency converter regulates conveying speed, finishing pigmented coating and top coating at a time to prevent repeated pollution and improve production effiency.

7.UV leveling machine adopts PID intelligent control instrument and controlled module heating system, which has the characteristics of high precision for temperature control and electricity saving.

The products are suitable for door frame, wooden line, photo frame, flooring molding, marble waistline and aluminum and so on.

-

The door

-

Moulding

-

Photo frame

-

The anchor line

-

Marble frieze

-

Aluminum profiles

-

Aluminum profile

Touch the beauty of technology

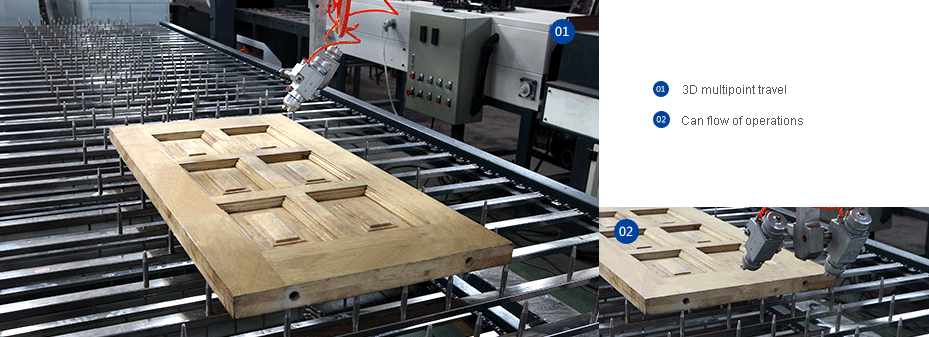

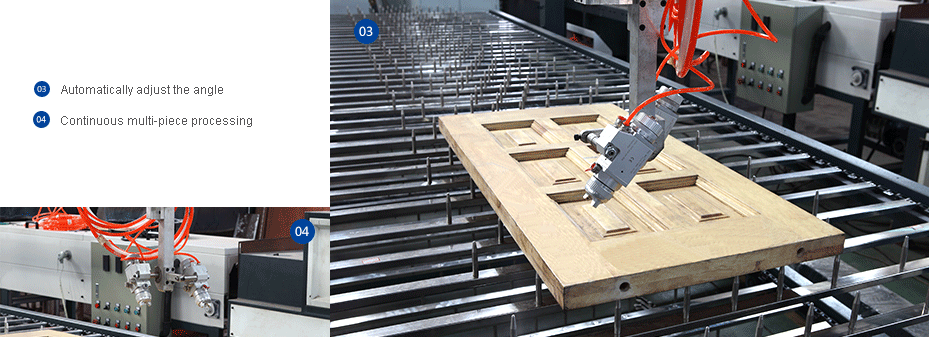

The pursuit of spraying technology and uphold the innovative attitude, so that Walton became the world's outstanding brand of CNC painting. Careful and reasonable design, to the perfect realization of the processing technology, are all embodies the revolutionary success of technology, harsh skills continue to go beyond innovation into the industry, so that doubling the value of the production line strength.

Intelligent parameter control, so that more intuitive and accurate processing.

By the Wharton NC joint research and development of automated painting system, with optimized process structure, and strictly calculate the amount of paint output, etc., which greatly enhance the intelligent application, reduce paint loss, the cost of the source for the user to control; programmable and real-time control can either To achieve continuous high-volume operations, but also real-time adjustment for the case; a full set of easy to use system without additional skills training